The Sound of Silence: Introducing the DrARTEX Electra EV Range

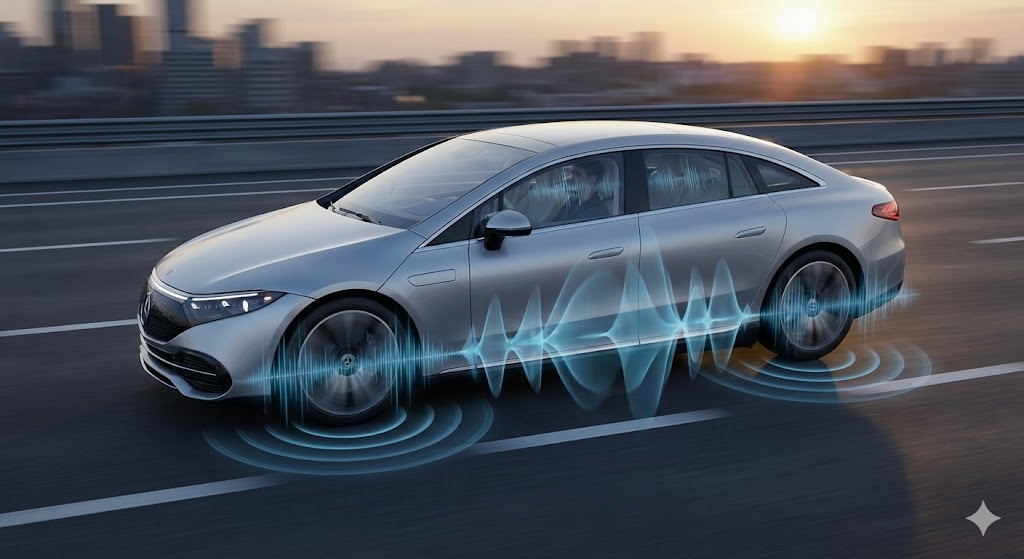

The automotive world has changed. The internal combustion engine—once the primary source of vehicle noise—is disappearing. In its place, the electric motor offers a near-silent powertrain. However, this silence unveils a new enemy: road noise, wind turbulence, and tire rumble that were previously masked by the engine.

For EV owners, the challenge is paradoxical: you need effective soundproofing to maintain that “luxury silence,” but traditional heavy bitumen mats kill your battery range.

Enter the DrARTEX Electra EV range. This isn’t just an update to our catalog; it is a fundamental reimagining of car acoustics, utilizing revolutionary Aerospace Mastic (ASRM) technology to solve the weight-vs-silence equation.

The Aerospace Advantage: Why Electra is Different

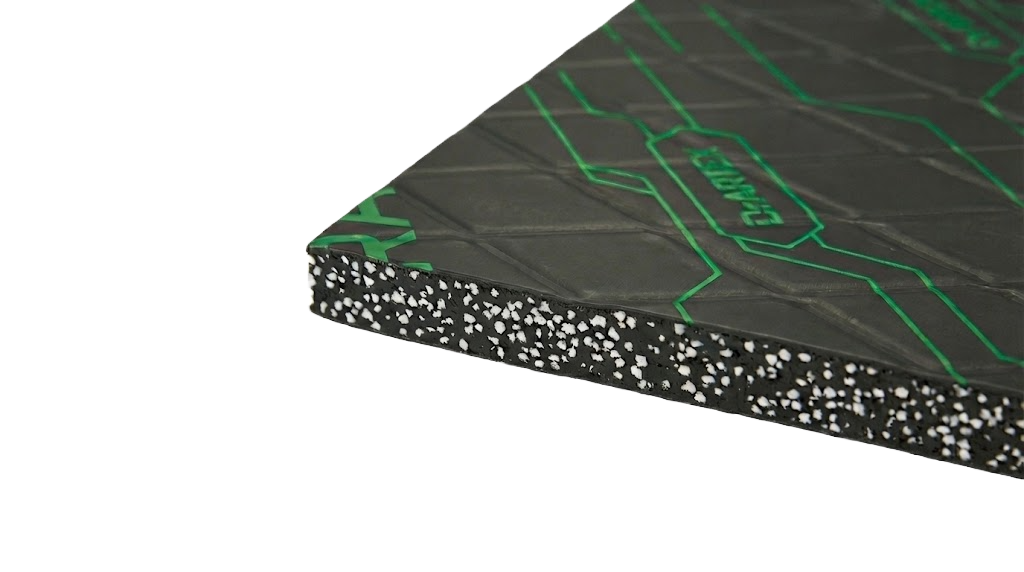

Unlike previous generations of soundproofing (and the vast majority of the current market) which rely on heavy butyl rubber or bitumen, the Electra line is built on our proprietary Aero Sphere Reinforced Mastic (ASRM). By infusing the polymer matrix with stochastic hollow ceramic “aero-granules,” we have achieved a material density as low as 0.58–0.65 g/cm³—roughly half that of standard mastic.

This means you get high mechanical loss factors (MLF) and vibration absorption at a fraction of the weight, ensuring your EV’s range remains unaffected.

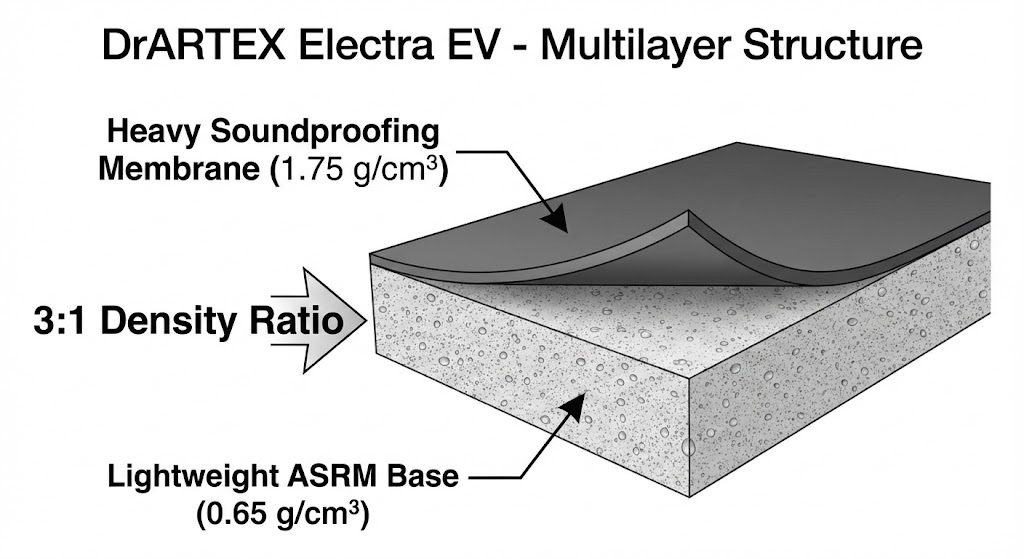

The “Mass Law” Revolution

The Electra range leverages physics, not just bulk. Our multilayer products—EV 7.0 Black and EV 9.0 Green—utilize a sophisticated “sandwich” structure. By bonding a Heavy Soundproofing Membrane (1.75 g/cm³) to a lightweight ASRM base (0.65 g/cm³), we create a 3:1 density ratio.

This specific ratio unlocks the “Mass Law” principle, delivering sound isolation capabilities (ΔR) up to 28% higher than standard single-layer solutions, targeting the deep, low-frequency rumble that plagues electric vehicles.

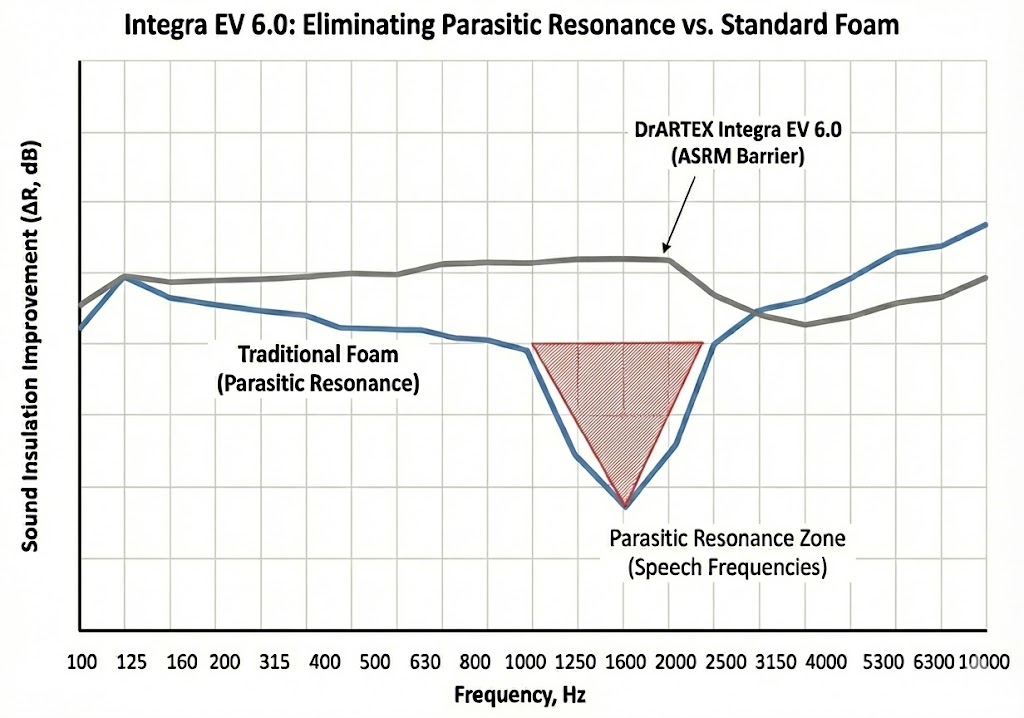

Killing the Resonance: Integra & VBB

Perhaps the biggest leap forward lies in our new “Second Layer” insulators: Integra EV 6.0 and VBB EV 7.0.

Traditional market solutions often use polyethylene foam as a second layer. While cheap, foam creates a “parasitic resonance zone” in the critical 1,000–2,000 Hz range (human speech frequencies), actually reducing insulation effectiveness.

We have replaced the foam entirely with our lightweight ASRM. The result?

- Zero Resonance: A linear sound barrier effective from 150 Hz to 10,000 Hz.

- Structural Rigidity: The Integra EV 6.0 increases body steel stiffness by up to 85%, drastically reducing panel vibration.

- Thermal Stability: Operates flawlessly from -40°C to +140°C.

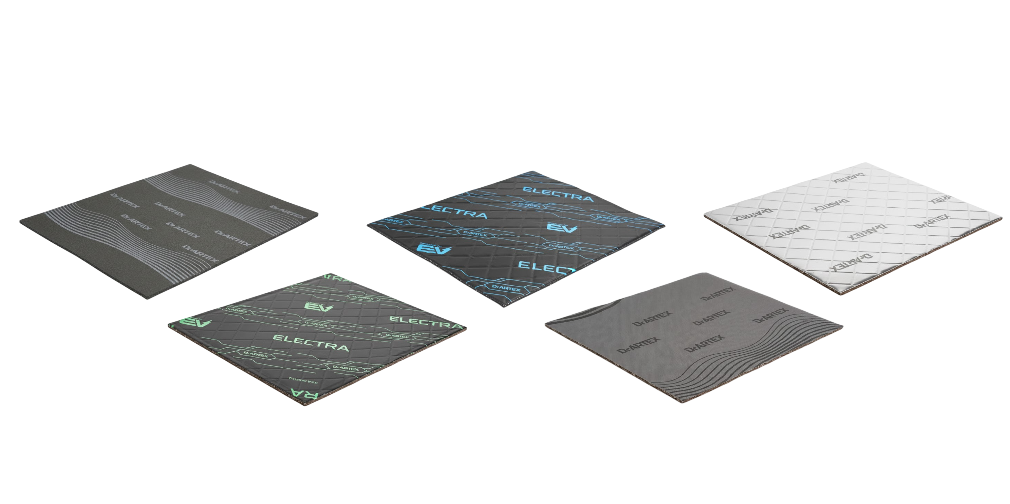

The New Lineup at a Glance

- EV 2.5 Silver & 5.0 Blue: The lightest vibration dampers in their class.

- EV 9.0 Green: Multilayer barriers for maximum isolation.

- Integra EV 6.0 & VBB EV 7.0: Advanced second-layer insulators that eliminate foam resonance.

With SGS certification guaranteeing safety and zero toxic emissions, the Electra EV range is the future of car soundproofing—lighter, quieter, and smarter.